Top Qs

Timeline

Chat

Perspective

Robotic arm

Type of mechanical arm with similar functions to a human arm From Wikipedia, the free encyclopedia

Remove ads

A robotic arm is a type of mechanical arm, usually programmable, with similar functions to a human arm; the arm may be the sum total of the mechanism or may be part of a more complex robot.[1] The links of such a manipulator are connected by joints allowing either rotational motion (such as in an articulated robot) or translational (linear) displacement.[2][3] The links of the manipulator can be considered to form a kinematic chain. The terminus of the kinematic chain of the manipulator is called the end effector and it is analogous to the human hand. However, the term "robotic hand" as a synonym of the robotic arm is often proscribed.

Remove ads

Classification

A serial robot arm can be described as a chain of links that are moved by joints which are actuated by motors. An end-effector, also called a robot hand, can be attached to the end of the chain. As other robotic mechanisms, robot arms are typically classified in terms of the number of degrees of freedom. Usually, the number of degrees of freedom is equal to the number of joints that move the links of the robot arm. At least six degrees of freedom are required to enable the robot hand to reach an arbitrary pose (position and orientation) in three dimensional space. Additional degrees of freedom allow to change the configuration of some link on the arm (e.g., elbow up/down), while keeping the robot hand in the same pose. Inverse kinematics is the mathematical process to calculate the configuration of an arm, typically in terms of joint angles, given a desired pose of the robot hand in three dimensional space.[citation needed]

Remove ads

Types

- Cartesian robot / Gantry robot: Used for pick and place work, application of sealant, assembly operations, handling machine tools and arc welding. It is a robot whose arm has three prismatic joints, whose axes are coincident with a Cartesian coordinator.

- Collaborative robot / Cobot: Cobot applications contrast with traditional industrial robot applications in which robots are isolated from human contact. Cobot has a large variety of applications such as: commercial application, robotic research, dispensing, material handling, assembly, finishing, and quality inspection. Cobot safety may rely on lightweight construction materials, rounded edges, and the inherent limitation of speed and force, or on sensors and software that ensures safe behavior.

- Cylindrical robot: Used for assembly operations, handling at machine tools, spot welding, and handling at die casting machines. It is a robot whose axes form a cylindrical coordinate system.

- Spherical robot / Polar robot: Used for handling machine tools, spot welding, die casting, fettling machines, gas welding and arc welding. It is a robot whose axes form a polar coordinate system.[4]

- SCARA robot: Used for pick and place work, application of sealant, assembly operations and handling machine tools. This robot features two parallel rotary joints to provide compliance in a plane.

- Articulated robot: Used for assembly operations, diecasting, fettling machines, gas welding, arc welding and spray-painting. It is a robot whose arm has at least three rotary joints.

- Parallel robot: One use is a mobile platform handling cockpit flight simulators. It is a robot whose arms have concurrent prismatic or rotary joints.

- Anthropomorphic robot: It is shaped in a way that resembles a human hand, i.e. with independent fingers and thumbs.

|

|

|

|

Remove ads

Notable robotic arms

Summarize

Perspective

Four notable manufacturers of robotic arms include FANUC, ABB, Yaskawa, and KUKA.

FANUC was established in Japan in 1972. As of 2023, they have shipped over 1 million robots.[7] In 2022, VW Group purchased 1,300 FANUC arms for automobile production.[8] Additionally, FANUC announced in 2025 that it sold 50 more robots for car painting.[9] In November 2025, FANUC unveiled a new robot arm aimed to target food handling and cleaning applications.[10]

ABB was established in Switzerland in 1988. In October 2025, ABB announced that its industrial robotics division was sold to the Japanese conglomerate SoftBank for USD$5.4 billion.[11][12] In May 2025, ABB showed off a collaboration with California restaurant Burgerbots. The arms were capable of assembling customized burgers in under 30 seconds.[13]

Yaskawa was established in Japan in 1915 and started developing the MOTO arm series in the 1960’s.[14] Their first robot arm, the Motoman-L10, started production in 1977. In 2021, Yaskawa announced that over 500,000 Motoman robots had been sold.[15] Yaskawa Europe has partnered with the Netherlands-based vision AI company Fizyr to create industrial robot arms, with ventures in automotive manufacturing and dishwashing.[16][17]

KUKA was established in Germany in 1898 and began industrial robot development in 1971.[18] In 1973, KUKA introduced FAMULUS, the first electric six-axis robot arm.[19] In 2008, KUKA released the KR 1000 Titan, which was the first robot arm capable of lifting 1000 kilograms.[20] Since at least 2014, Tesla automotive factories have used KUKA arms to manufacture products like the Tesla Model X, Tesla Model 3, and the Tesla Cybertruck.[21][22][23]

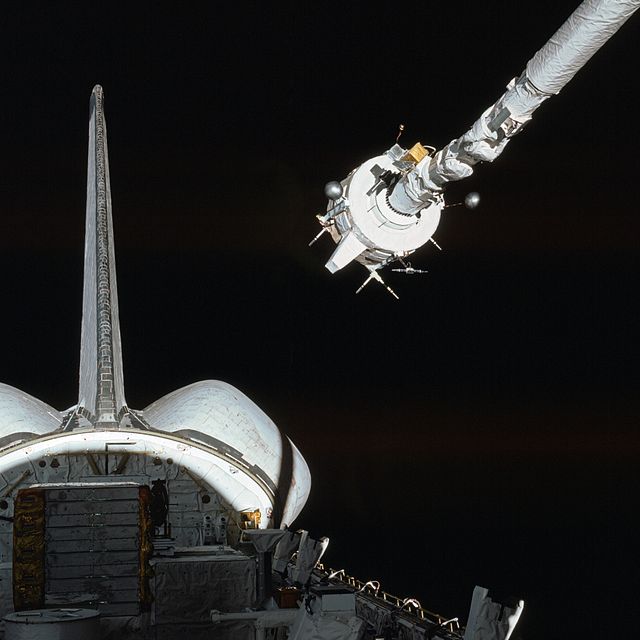

In space, the Canadarm and its successor Canadarm2 are examples of multi degree of freedom robotic arms. These robotic arms have been used to perform a variety of tasks such as inspection of the Space Shuttle using a specially deployed boom with cameras and sensors attached at the end effector, and also satellite deployment and retrieval manoeuvres from the cargo bay of the Space Shuttle.[24]

The Curiosity and Perseverance rovers on the planet Mars also use robotic arms.[25][26][27][28] Additionally, Perseverance has a smaller sample caching arm hidden inside its body below the rover in its caching assembly.

TAGSAM is a robotic arm for collecting a sample from a small asteroid in space on the spacecraft OSIRIS-REx.[29]

The 2018 Mars lander InSight has a robotic arm called the IDA, it has a camera, grappler, and is used to move special instruments.[30]

Remove ads

Low-cost robotic arms

In the decade of 2010 the availability of low-cost robotic arms increased substantially. Although such robotic arms are mostly marketed as hobby or educational devices, applications in laboratory automation have been proposed, like their use as autosamplers.[31][32]

Open-source robotics arms such as MeArm[33] have further reduced costs and enabled iterative community improvements to designs.

Robotic hands

The end effector, or robotic hand, can be designed to perform any desired task such as welding, gripping, spinning etc., depending on the application. For example, robot arms in automotive assembly lines perform a variety of tasks such as welding and parts rotation and placement during assembly. In some circumstances, close emulation of the human hand is desired, as in robots designed to conduct bomb disarmament and disposal.[34]

Remove ads

Artificial intelligence and machine learning

Summarize

Perspective

The significance of artificial intelligence and machine learning in robotic arm functioning and control has grown over the past few years. Even in unstructured surroundings, arms can identify and control a variety of items. This is possible because of vision-based AI systems. Motion planning, adaptive grasping, and the ability for robots to learn tasks from human examples are all made possible by machine learning. These features have expedited the usage of robotic arms in medical surgery, autonomous warehouses, and collaborative robots, among other applications.[35]

These AI-powered robotic arms are used more widely in the industrial sectors, logistics, healthcare, and also in the agricultural sectors. They increase productivity, eliminate human error, and do repetitive or precision-intensive activities faster than humans, such as assembling electronics, quality checking, and aiding in surgeries. These intelligent robotic arms automation helps reduce labor shortages and operating expenses across a number of different industries.[36][37]

The usage of edge computing, which allows robots to interpret sensor data in real time and make choices, is one recent advancement that has improved reaction times in fast-paced sectors. AI and sophisticated sensing are being used by collaborative robots, sometimes known as "cobots," to securely assist people. During joint work, they instinctively modify their motions. Robotic arms will also grow more autonomous, flexible and adaptive as machine learning and artificial intelligence advance, carrying out an ever widening range of activities in a variety of sectors.[38][39]

Remove ads

Machine learning applications

Summarize

Perspective

AI-capable robotic arms are increasingly essential in a variety of industries, including manufacturing, shipping, healthcare, and agriculture. These robotic arms are used in manufacturing to do intricate and repetitive jobs with exceptional speed and accuracy, such as welding automotive parts and assembling electronic components. Machine learning algorithms that adapt to minute changes in components enable these jobs, increasing quality and reducing waste.[40][41] AI-enabled robotic arms help solve manpower shortages and boost operational efficiency in logistics and warehousing by facilitating sorting, packaging, and palletizing with improved speed and precision.[42] Robotic-assisted surgeries are one example of a healthcare application where AI-driven arms increase dexterity and stability, allowing for less invasive treatments and faster recovery.[43] AI-powered manipulators are also used in agricultural robots for precise planting, harvesting, and crop monitoring, maximizing resource efficiency and yield quality.[44]

These robotic arms are further equipped with real-time sensor processing and autonomous decision-making capabilities, made possible by real time data analytics performed directly on robot and integrated AI systems. Collaborative robots, that are outfitted with advanced sensors and artificial intelligence may work securely alongside people, dynamically modifying their actions to improve both productivity and safety.[45][46] A growing role for robotic arms is indicated by the ongoing development of machine learning models and sensor integration, which gradually increases their autonomy, adaptability, and range of applications in both existing and emergent industries.[47]

Remove ads

See also

References

External links

Wikiwand - on

Seamless Wikipedia browsing. On steroids.

Remove ads