Top Qs

Timeline

Chat

Perspective

Fiber pull-out

One of the failure mechanisms in fiber-reinforced composite materials From Wikipedia, the free encyclopedia

Remove ads

Fiber pull-out is one of the failure mechanisms in fiber-reinforced composite materials.[1] Other forms of failure include delamination, intralaminar matrix cracking, longitudinal matrix splitting, fiber/matrix debonding, and fiber fracture.[1] The cause of fiber pull-out and delamination is weak bonding.[2]

Work for debonding, [3]

where

- is fiber diameter

- is failure strength of the fiber

- is the length of the debonded zone

- is fiber modulus

In ceramic matrix composite material this mechanism is not a failure mechanism, but essential for its fracture toughness,[4] which is several factors above that of conventional ceramics.

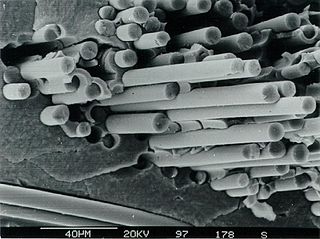

The figure is an example of how a fracture surface of this material looks like. The strong fibers form bridges over the cracks before they fail at elongations around 0.7%, and thus prevent brittle rupture of the material at 0.05%, especially under thermal shock conditions.[5][page needed] This allows using this type of ceramics for heat shields applied for the re-entry of space vehicles, for disk brakes and slide bearing components.

Remove ads

References

Wikiwand - on

Seamless Wikipedia browsing. On steroids.

Remove ads