Top Qs

Timeline

Chat

Perspective

Simatic

Series of programmable logic controllers From Wikipedia, the free encyclopedia

Remove ads

SIMATIC is a series of programmable logic controller and automation systems, developed by Siemens. Introduced in 1958, the series has gone through four major generations, the latest being the SIMATIC S7 generation. The series is intended for industrial automation and production.

This article has multiple issues. Please help improve it or discuss these issues on the talk page. (Learn how and when to remove these messages)

|

The name SIMATIC is a registered trademark of Siemens. It is a portmanteau of "Siemens" and "Automatic".

Remove ads

Function

As with other programmable logic controllers, SIMATIC devices are intended to separate the control of a machine from the machine's direct operation, in a more lightweight and versatile manner than controls hard-wired for a specific machine. Early SIMATIC devices were transistor-based, intended to replace relays attached and customized to a specific machine. Microprocessors were introduced in 1973, allowing programs similar to those on general-purpose digital computers to be stored and used for machine control.[1] SIMATIC devices have input and output modules to connect with controlled machines. The programs on the SIMATIC devices respond in real time to inputs from sensors on the controlled machines, and send output signals to actuators on the machines that direct their subsequent operation.

Depending on the device and its connection modules, signals may be a simple binary value ("high" or "low") or more complex. More complex inputs, outputs, and calculations were also supported as the SIMATIC line developed. For example, the SIMATIC 505 could handle floating point quantities and trigonometric functions.[2]

Remove ads

History

Summarize

Perspective

On April 2, 1958 the name Simatic (composed of "Siemens" and "Automatic") was registered with the German Patent and Trademark Office (DIN) as a registered trademark of the company Siemens.

A year later, in 1959, the Simatic G[3] was launched on the market, a system that could replace relay logic with a hard-wired programmed logic controller (based on the use of Germanium transistors). The system was launched under the name "Building-Block System for Solid-State Controls".

In 1964, the Simatic N (1964) was launched (hard-wired programmed logic controller) - based on Silicon transistors.

In 1973, the Simatic S3 was launched, the first microprocessor-based Simatic system that implemented programmable logic.[4]

In 1979, the Simatic S5 series was launched, a series that was maintained until 2000. Automation systems based on Simatic S5 are still functional worldwide. S5 systems were programmed using the STEP 5 software system. In 1984 the Simatic S5 U (universal) programmable controller series is introduced.

In 1994, the Simatic S7 series was launched, a series based mainly on the S7-200 controllers (dedicated to simple automation systems), S7-300 (suitable for almost any automation system) and S7-400 (dedicated to large and very large automation projects). All controllers in these series allow networking, especially in Profibus or Industrial Ethernet networks.

In 1996 Siemens presented the concept of "Totally Integrated Automation", initially a concept referring to the interconnectivity of automation equipment.[5]

In 2009, the S7-1200 series of PLCs was launched, a series that replaced the S7-200 series.

In 2011, the TIA Portal (Totally Integrated Automation Portal) software package was also launched, a software platform dedicated to the complex programming of automation systems.

In 2013, the S7-1500 series appeared on the market, a new generation of programmable logic controllers intended to replace the S7-300 and S7-400 series over time.

S7-1200 G2, a second generation of the S7-1200, was launched in December 2024.

Remove ads

Controllers

Summarize

Perspective

SIMATIC control systems (PLC) are designed to automate as much of the control of industrial plants as possible. Through the system inputs and outputs, it can monitor and control process elements (operation flow, mechanical element status, temperature, pressure) reducing the need for continuous supervision by a human operator.

The operating logic is stored in the form of a software program in the memory of a Central Processing Unit type control system. The automation system is modular and, in addition to the CPU, can be equipped with various digital and/or analog peripheral modules, as well as intelligent control modules. The modules can be configured centrally (mounted in close proximity to the CPU unit) or decentralized, close to the controlled plant. The range of controllers extends from small, compact controllers to high-performance PLC systems. What all Simatic controllers have in common is their robustness against electromagnetic interference (e.g. Simatic-S7 complies with the requirements of Directive 2014/30/EU on electromagnetic compatibility and climatic stress - e.g. 0 to + 60 °C ambient temperature during operation). Simatic is programmed using STEP 7 (formerly STEP 5) programming software or software from third-party manufacturers.

Siemens has developed more product lines to date. First versions were hard-wired, the first processor based series being SIMATIC S3

SIMATIC S3

(starting from 1973)

S3 was based on hard-wired logic SIMATIC C3.

- Example: Simatic S3-111

Simatic S5

(1979 - 2000)

The S5 line was sold in various chassis configurations. Within each chassis style, several CPUs were available, with varying speed, memory, and capabilities. Some systems provided "fail-safe" control, used for safety applications or redundant CPU operation for ultra-high-reliability control, as used in pharmaceutical manufacturing, for example.

Each configuration was built starting from the central unit to which the various input and output modules, communication or modules for special functions were attached. The compact variants were configured by directly coupling the modules onto the support rail, the complex variants were configured by mounting modular boards in a dedicated drawer.

- Simatic S5-010 – Modular PLC system

- Simatic S5-010K – Variant for injection molding machines (Kunststoffspritz).

- Simatic S5-010W – Variant for machine tools (Werkzeugmaschinen) or positioning systems.

- Simatic S5-90U – Compact control units

- Example: 6ES5090-8MA0x / S5-90 / 4 kByte RAM / Integrated 230 V AC power supply, 10 binary inputs, 6 relay outputs directly on the CPU

- Simatic S5-95[6] – Compact control units

- Simatic S5-95F – Failsafe version - integrated safety functions

- Simatic S5-95U[7] – universal version

- Simatic S5-100U[8] – Modular unit

- Simatic S5-101 – Compact unit

- Simatic S5-105R – Modular system in 19-inch drawer. Programming only in LAD ("R" stands for Relay - programming in LAD = relay diagram)

- Simatic S5-110 – Modular system

- Simatic S5-110A – Modular

- Simatic S5-110F[11] – Failsafe version - integrated safety functions

- Simatic S5-110S – Modular, drawer mounting with external I/O bus

- Simatic S5-115 – Modular system, fanless central unit, (fans for certain drawer types), different memory capacities depending on version, expandable memory with plug-in modules

- Simatic S5-115F – Failsafe version - integrated safety functions

- Simatic S5-115H – Redundant version (High Availability)

- Simatic S5-115U[12] – Universal version

- Simatic S5-130 – Mid-range modular system (performance-wise)

- Simatic S5-130A – Robust version (encapsulated modules)

- Simatic S5-130K – Compact version (cardboard in drawer)

- Simatic S5-130W – Cardboard in drawer version for industrial process automation

- Simatic S5-135U – Mid-range modular system (performance-wise). The first Simatic system that allows multiprocessor configurations (up to 4 central units in parallel). Each central unit has its own PLC program, its own memory areas, counters and timers. Communication between the processors can be achieved via a common memory area (Dual-Port-RAM) or via data blocks (DB blocks).

- Ex.: 6ES5 920-3UA1x, 6ES5 921-3UA1x, 6ES5 922-3UA1x, 6ES5 928-3UA1x, 6ES5 928-3UA2x, 6ES5 928-3UB1x, 6ES5 928-3UB2x, ...

- Simatic S5-150 – Modular system with ventilated drawer for complex automation or central coordination systems, introduced on the market in 1980.

- Simatic S5-150A – Robust design variant (encapsulated modules)

- Simatic S5-150K – Compact design variant (card boards in drawer)

- Simatic S5-150S – Drawer design variant (card boards in drawer)

- Simatic S5-150U – Drawer design variant (card-type boards in the drawer)

- Ex.: 6ES5 924..., 6ES5 925..., 6ES5 926..., 6ES5 927...

- Simatic S5-155 – Modular system, with ventilated drawer, for complex automation, allows single- or multi-processor configurations.

- Simatic S5-155H – Redundant version ("High Availability")

- Simatic S5-155U - Universal version

- Ex.: 6ES5 946..., 6ES5 947..., 6ES5 948...

Simatic S7 (S7-200, S7-300, S7-400)

(since 1994)

The first entries in the S7 line were released in 1994, available under three performance classes: S7-200, S7-300 and S7-400. The introduction of SIMATIC S7 saw also the release of a new fieldbus standard Profibus, and the pioneer use of industrial Ethernet to facilitate communication between automation devices. The great success of the S7-300 CPU family in particular helped to cement the role of Siemens as one of the global leaders in automation technology. These series are expected to be phased out in 2033.[13]

Simatic S7-200

(phased-out - SIOS, 2017-07-26)

A series of small (80 mm x 62 mm), fast (0.22 μs binary execution time) PLC modules with an integrated RS 485 interface (PPI Interface = Point to Point Interface).

- for low-complexity automation applications

- Programmable using the Step 7 MicroWin software (originally Step 7 MicroDos).

- Although no longer marketed as such, S7-200 units are still used for the PLC units integrated in the Sinumerik 828D CNC Numerical Controls series.

Simatic S7-300 [14]

Modular PLC system (but there are also some compact CPU units, with integrated Inputs/Outputs). Communication with other devices is possible via the integrated RS 485 (MPI = Multi Point Interface), Profibus, Profinet and Ethernet interfaces.

- modular system, expansion of the number of inputs/outputs by adding modules

- for automation applications of low or medium complexity

- system programming is done using the STEP 7 software package.

- PLC program storage is done on an MMC card inserted in the CPU unit.

The system consists of:

- A CPU unit that also includes communication functions (MPI, Profibus or Profinet, depending on the chosen variant)

- SM modules for connecting inputs and outputs (digital or analog)

- Optional: IM interface modules or SP communication processors for various types of communication buses

- Optional: FM function modules such as high-speed counters, positioning (closed/open loop), PID control, etc.

Simatic S7-300: Control units (extract)

- CPU 312 32 KB working memory, MPI interface; storage medium: MMC card

- CPU 314 128 KB working memory, MPI interface; storage medium: MMC card

- CPU 315-2DP 256 KB working memory, MPI interface, ProfiBus DP master/slave interface; storage medium: MMC card

- CPU 315-2 PN/DP 384 KB working memory, dual interface MPI/PROFIBUS DP master/slave, Ethernet/PROFINET interface with 2-port switch; MMC card

- CPU 317-2 DP 1 MB working memory, MPI interface, PROFIBUS DP master/slave interface; MMC card

- CPU 317-2 PN/DP 1 MB working memory, dual interface MPI/PROFIBUS DP master/slave, Ethernet/PROFINET interface with 2-port switch; MMC card

- CPU 319-3 PN/DP 2 MB working memory, dual interface MPI/PROFIBUS DP master/slave, PROFIBUS DP master/slave, Ethernet/PROFINET interface with 2-port switch; MMC card

Simatic S7-300F

Modular PLC system, based on S7-300, with extended functions for process control in which functional safety ("safety functionality") plays an important role.

- the system allows the achievement of functional safety requirements SIL 1 to SIL 3 according to IEC 61508, PL a to PL e according to EN ISO 13849-1, Cat 1, 2, 3 and 4 according to EN 954-1.

- the system implements the functionality of an S7-300 system, the functional safety functions only extend the possibilities of the system.

- special dedicated input / output modules ("failsafe") may be required to implement the safety functions, which can also be connected together with the usual input / output modules (mixed use).

- the system is programmed using the STEP 7 software package, for safety functions the STEP 7 Distributed Safety extension package is required.

Simatic S7-300 SIPLUS

Modular PLC system, based on S7-300, for use in adverse environmental conditions (-25 ... 60 °C, high humidity, frost, etc.).

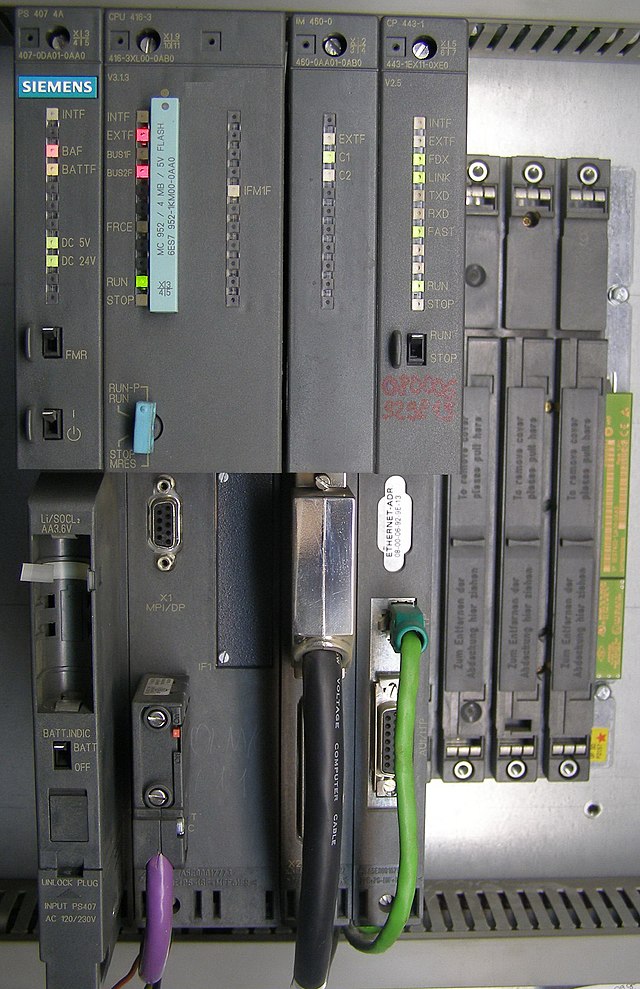

Simatic S7-400 [15]

Modular PLC system, with dedicated drawer mounting. Communication with other devices is possible via the integrated RS 485 (MPI = Multi Point Interface), Profibus, Profinet and Ethernet interfaces.

- modular system, expansion of the number of inputs / outputs by adding modules in the drawer or distributed periphery.

- for medium and high complexity automation applications.

- system programming is done using the STEP 7 software package

- PLC program storage is done on the card

- allows the use of multiple CPU units in a single system (multi-processor) for complex applications.

The system consists of:

- A CPU unit that also includes communication functions (MPI, Profibus or Profinet, depending on the chosen variant)

- SM modules for connecting inputs and outputs (digital or analog)

- Optional: IM interface modules or SP communication processors for various types of communication buses

- Optional: FM function modules such as high-speed counting, positioning (closed/open loop), PID control, etc.

S7-400H

Redundant S7-400 system, with two central units and the possibility of connecting I/O modules in pairs, for extended availability.

S7-400F / S7-400FH

S7-400 "failsafe" system with safety functions, in single-channel or redundant version.

S7-400F: single-channel, single set of I/O

S7-400FH: redundant, I/O in pairs, switchable or single-channel, I/O in pairs

Simatic WinAC-RTX

SIMATIC WinAC RTX is a SIMATIC software control system, which can be installed on an industrial PC. The I/O modules can be connected via PROFIBUS or PROFINET using the Ethernet interface or PCI expansion cards.

Simatic S7 (S7-1200, S7-1500)

(since 2009)

In April 2009, Siemens initiated a generational change in the Simatic S7 controllers by launching, first, the S7-1200 controller family, then, in 2012, S7-1500.[16]

Simatic S7-1200

(since 2009)

S7-1200[17] is a family of small (approx. 100 mm × 75 mm), compact PLC units, intended for low-complexity control solutions. It has up to 150 kB of working memory, 2 Mbytes of integrated program memory that can be expanded up to 24 Mbytes and an execution time for bit instructions of approximately 0.1 μs. Communication with other devices is possible via the integrated Profinet and Ethernet interfaces or via optional communication modules.

- modular system, expansion of the number of inputs / outputs by adding modules

- for automation applications of low or medium complexity

- system programming is done using the software package TIA STEP 7 (Totally Integrated Automation Step 7).

- PLC program storage is done internally, on the EEPROM integrated in the module, or on the Simatic Memory Card (SD Card).

The system consists of:

- A CPU unit that also includes Profinet communication functions and a number of digital or analog inputs and outputs.

- Optional: SM modules for expanding the number of inputs and outputs (digital or analog).

- Optional: CM communication modules for various types of communication buses (RS232, ModBus, GPRS, ...).

- Optional: 4-port Ethernet network switch

- Optional: Connection module for SIWAREX weighing systems

- Optional: "Condition Monitoring" module for monitoring drive systems (wear, motor bearings, etc.)

Simatic S7-1200: Control units (extract)

- CPU 1211C DC/DC/DC, AC/DC/relay, DC/DC/relay, 50 KB working memory, 6I/4Q/2AI, expandable with expansion board

- CPU 1212C DC/DC/DC, AC/DC/relay, DC/DC/relay, 75 KB working memory, 8I/6Q/2AI, expandable with expansion board and up to 2 I/O modules

- CPU 1214C DC/DC/DC, AC/DC/relay, DC/DC/relay, 100 KB working memory, 14I/10Q/2AI, expandable with expansion board and up to 8 I/O modules

- CPU 1215C DC/DC/DC, AC/DC/relay, DC/DC/relay, 125 KB working memory, 14I/10Q/2AI/2AQ, expandable with expansion board and up to 8 I/O modules

- CPU 1217C DC/DC/DC, 150 KB working memory, 14I/10Q/2AI/2AQ, expandable with expansion board and up to 8 I/O modules

- CPU 1212FC (failsafe) DC/DC/DC, DC/DC/relay, 100 KB working memory, 8I/6Q/2AI, expandable with expansion board and up to 2 I/O modules (including failsafe I/O)

- CPU 1214FC (failsafe) DC/DC/DC, DC/DC/relay, 125 KB working memory, 14I/10Q/2AI, expandable with expansion board and up to 8 I/O modules (including failsafe I/O)

- CPU 1215FC (failsafe) DC/DC/DC, DC/DC/relay, 150 KB working memory, 14I/10Q/2AI/2AQ, expandable with expansion board and up to 8 I/O modules (including failsafe I/O)

Simatic S7-1200 G2

(since 2024)

The S7-1200 G2, the second generation of programmable controllers in the S7-1200 range, was presented at the Hannover Messe 2024 edition [18] and launched on the market in December 2024 - January 2025, together with TIA-Portal v20.[19]

The S7-1200 G2 modules are not hardware compatible with those of the first generation. Compared to the first generation S7-1200, the new modules have improvements regarding:

- reduced execution time

- support for ProfiNet communication of Real-Time (RT) and Isochronous Real-Time (IRT) type

- support for Media Redundancy for Planned Duplication (MRPD) and Media Redundancy Protocol (MRP)

- Program memory of up to 300kB, data memory of up to 750kB, working memory of up to 8MB

- support for the use of SIMATIC Motion Library technology objects (TO_SpeedAxis, TO_PositioningAxis, TO_SynchronousAxis, TO_ExternalEncoder, TO_OutputCam, TO_CamTrack, TO_MeasuringInput, TO_Cam, TO_Kinematics)

- SIMATIC Controller Profiling

- Extended functionality regarding data security (event log, support for user and role management)

- Near Field Communication (NFC) connectivity. Allows diagnosis and parameterization of the CPU unit using a phone app (initially only I-OS). In 2025, few months after S7-1200 G2 series launch, the NFC interface was deactivated in a new firmware release.

Simatic S7-1200 G2: Control units (extract)

- CPU 1212C G2 DC/DC/DC, AC/DC/relay, DC/DC/relay, 150 KB program memory, 500kB data memory, 8DI/6DQ, expandable with expansion board

- CPU 1214C G2 DC/DC/DC, AC/DC/relay, DC/DC/relay, 250 KB program memory, 750kB data memory, 14DI/10DQ, expandable with one or two expansion boards

- CPU 1212FC G2 DC/DC/DC, DC/DC/relay, 150 KB program memory, 500kB data memory, 8DI/6DQ, expandable with expansion board

- CPU 1214C G2 DC/DC/DC, AC/DC/relay, DC/DC/relay, 250 KB program memory, 750kB data memory, 14DI/10DQ, expandable with one or two expansion boards

Simatic S7-1500

(since 2012)

At the press conference of the 2012 edition of the SPS/IPC/DRIVES trade fair in Nuremberg, Siemens presented the new Simatic S7-1500 controller which should gradually replace the units of the S7-300 and S7-400 series.[20] Motion control functions are now integrated into every CPU as standard, only extended functions such as kinematics requiring special PLC units from the S7-1500T series. Functional safety (up to SIL3 according to IEC 62061 and PL-e according to ISO 13849) is available in the failsafe S7-1500F CPU variants. The CPU units are equipped with Profinet interfaces as standard, have an integrated web server and a color display and can be expanded with up to 32 modules in the central drawer.

- modular system, expansion of the number of inputs / outputs by adding modules

- for automation applications of medium to high complexity

- system programming is done using the software package TIA STEP 7 (Totally Integrated Automation Step 7).

- PLC program storage is done on a Simatic Memory Card (SD Card).

Simatic S7-1500: Control units (excerpt)

- CPU 1511-1PN, 150KB Program, 1MB Data 6ES7511-1AK02-0AB0

- CPU 1511-1PN, 300KB Program, 1.5MB Data 6ES7511-1AL03-0AB0

- CPU 1513-1PN, 300KB Program, 1.5MB Data 6ES7513-1AL02-0AB0

- CPU 1513-1PN, 600KB Program, 2.5MB Data 6ES7513-1AM03-0AB0

- CPU 1515-2PN, 500KB Program, 3MB Data 6ES7515-2AM02-0AB0

- CPU 1515-2PN, 1MB Program, 4.5MB Data 6ES7515-2AN03-0AB0

- CPU 1516-3PN/DP, 1MB Program, 5MB Data 6ES7516-3AN02-0AB0

- CPU 1516-3PN/DP, 2MB Program, 7.5MB Data 6ES7516-3AP03-0AB0

- CPU 1517-3PN/DP, 2MB Program, 8MB Data 6ES7517-3AP00-0AB0

- CPU 1518-4PN/DP, 6MB Program, 60MB Data 6ES7518-4AP00-0AB0

- CPU 1518-4PN/DP MFP + C/C++ RT + OPC UA 6ES7518-4AX00-1AC0

Simatic S7-1500: Failsafe control units (extract)

- CPU 1511F-1PN, 225KB Program, 1MB data 6ES7511-1FK02-0AB0

- CPU 1511F-1PN, 450KB Program, 1.5MB Data 6ES7511-1FL03-0AB0

- CPU 1513F-1PN, 450KB Program, 1.5MB Data 6ES7513-1FL02-0AB0

- CPU 1513F-1PN, 900KB Program, 2.5MB Data 6ES7513-1FM03-0AB0

- CPU 1515F-2PN, 750KB Program, 3MB Data 6ES7515-2FM02-0AB0

- CPU 1515F-2PN, 1.5MB Program, 4.5MB Data 6ES7515-2FN03-0AB0

- CPU 1516F-3PN/DP, 1.5MB Program, 5MB Data 6ES7516-3FN02-0AB0

- CPU 1516F-3PN/DP, 3MB Program, 7.5MB Data 6ES7516-3FP03-0AB0

- CPU 1517F-3PN/DP, 3MB Program, 8MB Data 6ES7517-3FP00-0AB0

- CPU 1518F-4PN/DP, 9MB Program, 60MB Data 6ES7518-4FP00-0AB0

- CPU 1518F-4PN/DP MFP + C/C++ RT +OPC UA 6ES7518-4FX00-1AC0

Simatic S7-1500: SIPLUS (for extreme temperature, vibration, etc.)

- Most of the above modules can also be ordered in SIPLUS version

Simatic S7-1500 Technology: extended technology functions for implementing complex axis synchronizations or kinematic functions (Motion Control)

- CPU 151*T: S7-1500 CPU variants with extended technology functions

- CPU 151*TF: variants with extended technology functions and failsafe

Simatic S7-1500 "Fault-tolerant" and redundant:

- CPU 1513R-1 PN, 600KB program/2.5MB data 6ES7513-1RM03-0AB0

- CPU 1515R-2 PN, 1MB program/ 4.5MB data 6ES7515-2RN03-0AB0

- CPU 1517H-3 PN, 2MB program/8MB data 6ES7517-3HP00-0AB0

- CPU 1518HF-4 PN, 9MB program/60MB data 6ES7518-4JP00-0AB0

- CPU 1513R-1 PN, 300KB program/1.5MB data 6ES7513-1RL00-0AB0

- CPU 1515R-2 PN, 500KB program/ 3MB data 6ES7515-2RM00-0AB0

- SIPLUS S7-1500 CPU 1517H-3 PN 6AG1517-3HP00-4AB0

- SIPLUS S7-1500 CPU 1518HF-4 PN

Remove ads

Software

Summarize

Perspective

The first generations of Simatic control systems (Simatic G, Simatic S) were implemented using hard-wired programmed logic controllers. Simatic S3 was the first microprocessor-based control system that allowed programmable logic.

Simatic S5, launched in 1979, was initially programmed using special programming consoles and later using the STEP 5 software package, one of the first advanced PLC programming software.[21]

For programming the Simatic S7 300 and 400 systems, Siemens has launched the software package STEP 7, the Simatic S7 200 series being programmed with a separate software called STEP 7 MicroWin.

With the introduction of the S7 1200 and S7 1500 series controllers on the market, Siemens has launched a new software package called TIA Portal (Totally Integrated Automation Portal). It allows programming of the new generation S7 1200 and S7 1500 controllers as well as controllers from previous series.[22]

STEP 5

STEP 5 (name derived from STeuerungen Einfach Programmieren = easy programming of control systems) is a programming and diagnostic software for the Simatic S5 series of programmable controllers, originally released in 1979 only on the PG630 programming consoles, under the operating system CP/M. With the withdrawal of Simatic S5 systems from production, STEP 5 continued to be offered by Siemens but development of the software package was discontinued. The latest edition is version 7.2 (with upgrade to version 7.23 Hotfix 1 with patches) and can run (under certain conditions) on Windows 10 systems and is offered by Siemens for certain configurations of Field PG M6 programming consoles.

STEP 5 was offered in two versions:

Step 5 Standard, which can be used for programming, testing, commissioning and automatic generation of documentation for the Simatic S5-90U, S5-95/U/F, S5-100U, S5-101U, S5-115U/H/F, S5-135U, S5-150U and S5-155U/H series controllers.

Step 5 for mini PLCs, limited to the S5-90U, S5-95U/F and S5-100U controllers and allowing only a limited number of optional software packages: GRAPH Mini, COM IP 266, COM 95F, COM DG1, COM 521 BASIC.

Software modules

Since the first computers (Field PG programming consoles) had limited hardware resources (e.g. restrictions on RAM capacity), STEP 5 was developed modularly, in individual software packages that were launched (and loaded into memory) only when they were needed.[23] [SIOS ID:[24] 19417353]

LAD, CSF, STL

This module contains the editors for user programs. Programming of Simatic S5 PLCs can be done in one of the following languages:

- STL (STatement List, called AWL = Anweisungliste in German or IL = Instruction List according to IEC 61131-3). It is a low-level language, according to DIN 19239, similar to assembly language, with an extended set of instructions that offers great flexibility in writing and optimizing the program. Control of program execution is achieved using Jump, BE and function calls.

- LAD (Logical LADder, called KOP = Kontaktplan in German or LD according to IEC 61131-3). It is a graphical language according to DIN 19239 in which the user program is represented similar to a circuit diagram.

- CSF (Control System Flowchart, called FUP = Funktionsplan in German or FDB according to IEC 61131-3). It is a graphical language, according to DIN 40700, in which the user program is represented similar to an electronic diagram with logic gates.

XRF, COMP, REW

- XRF: This module allows the generation of cross references (XRF = Cross References, QL = Querverweisliste in German).

- COMP: Comparison of blocks in the offline project with those in the programmable controller (from the connected EPROM or from the connected online PLC, context-dependent), for example.

- REW: "Rewiring" function: search and replace an operand with another operand in all blocks of a STEP 5 project.

EPROM / EEPROM

It allows the transfer of the PLC program from PG (or PC) to EPROM (or EEPROM), from EPROM / EEPROM to PG / PC or the comparison of the program from PG / PC with that in EPROM / EEPROM. (PG = Programming Console, PC = Personal Computer).

Symbol Editor

An editor through which each operand can be assigned a symbol and a comment that can be viewed in program editors.

Optional COM modules

Various optional packages, such as GRAPH5 (for sequential programming), PG-NET (networking), KOMDOC (generate documentation), COM266 (for IP266 positioning module), COM723 (for WF723 CNC module), COM-ET200 (for distributed periphery), etc.

OB, PB, SB, FB/FX, DB/DX blocks

In STEP 5 the program can be structured into blocks whose execution can be controlled.

- OB: organization blocks: for program management.

- PB: program blocks: contain the user program structured according to functional or process requirements. When migrating a PLC program from STEP5 to STEP 7, PB blocks are converted to FC blocks but in the conversion guide they are assigned to FB blocks.

- SB: sequence blocks: blocks for programming sequencers. When using the GRAPH 5 module (software extension), the entire sequencer can be written in a single SB block.

- FB: function blocks: similar to FC blocks from S7 controllers.

- FX: extended function blocks: Similar to FB functions. They are not a new type of block, they are still FB blocks but, for certain CPU units, they allow the use of additional memory resources and their address area.

- DB: data blocks. They do not contain code and can be considered an extension of the working memory (the PLC working memory area, denoted F in STEP 5 and similar to the M area in STEP 7).

- DX: data blocks (extended): similar to DB blocks. They are not a new type of block, they are still DB blocks but, for certain CPU units, they allow the use of additional memory resources and their address range.

History of STEP5

STEP 7 MicroWin

(v1.0 - v4.0, originally named STEP 7 MicroDOS)

was the programming and diagnostic software for the S7 200 series of programmable controllers, originally released in 1995. Last version was STEP 7-Micro/WIN V4.0 SP9 released in 2012.

STEP 7

(v1.0 - v5.7)

STEP 7[43] (name derived from STeuerungen Einfach Programmieren = easy programming of control systems) is a programming and diagnostic software for the programmable controllers of the Simatic S7, SIMATIC C7 and SIMATIC WinAC series.

STEP 7 can be used in the various stages of an automation project:

- description and parameterization of the hardware configuration.

- specification and parameterization of communication interfaces.

- programming of PLC automation logic.

- commissioning, testing and troubleshooting of automation systems.

- documentation and archiving of projects.

STEP 7 is designed as a modular software package that offers various utilities for the development of automation projects.

Simatic Manager: For the central management of all utilities and data of the SIMATIC S7, C7 or WinAC automation project.

Hardware Editor: For configuring the automation system and parameterizing the modules that can be set.

Symbol Editor: For defining the global tags used, the symbolic names, data types and comments for them.

Program Editor: For editing user programs, using one of the standardized PLC programming languages (according to EN 61131-3):

- STL (Statement List, called AWL = Anweisungliste in German or IL = Instruction List according to IEC 61131-3). It is a low level language, according to DIN 19239, similar to assembly language, with an extended set of instructions that provides great flexibility in writing and optimizing the program. Control of program execution is achieved using Jump, BE and function calls.

- LAD (Logical LADder, called KOP = Kontaktplan in German or LD according to IEC 61131-3). It is a graphical language according to DIN 19239 in which the user program is represented similar to an electrical diagram (American format - ladder diagram). In most cases the program displayed in LAD is easier to understand and the on-line debugging is intuitive and easier than debugging a program displayed in STL. However, in STEP 7 (up to v5.x inclusive) user programs are saved and transferred to the Simatic S7 programmable controller only in STL (AWL). LAD is only a form of displaying the user program that does not contain all the instructions available in STL.

- FBD (Function Block Diagram, FBS – Funktionsbausteinsprache in German or FDB according to IEC 61131-3; similar to the CSF language of STEP 5). It is a graphical language, according to DIN 40700, in which the user program is represented similar to an electronic diagram with logic gates. In most cases the program displayed in CSF/FBD is easier to understand and the on-line debugging is intuitive and easier than debugging a program displayed in STL. However, in STEP 7 (up to and including v5.x) user programs are saved and transferred to the Simatic S7 programmable controller only in STL (AWL). CSF/FBD is only a form of displaying the user program that does not contain all the instructions available in STL.

Optionally, STEP 7 also offers the following languages (usually subject to the purchase of a license):

- S7-SCL (Structured Control Language, ST according to IEC 61131-3). It is a high-level language, based on the PASCAL language, which allows the use of complex language structures such as REPEAT-UNTIL, WHILE-DO, IF-THEN-ELSE, CASE, etc.

- S7-Graph (Sequential Function Diagram, SFC according to IEC 61131-3). A graphical programming language, which allows the implementation of sequential control structures, based on the concept of binary Petri nets. An S7-Graph program consists of a number of steps, each step having associated PLC program actions / equations, and a number of transitions that allow the transition from a certain step to another upon the fulfillment of certain conditions.

- S7-HiGraph (Siemens-specific, not conforming to IEC 61131-3 standardization). A graphical programming language, similar to S7-Graph, that allows the implementation of advanced binary control structures, similar to state diagrams.

- S7-CFC (Continuous Function Chart, Siemens-specific, not conforming to IEC 61131-3 standardization). A graphical editor used to create the entire PLC program structure from ready-to-program library blocks. In the editor these blocks are selected in graphs, parameterized and interconnected. CFCs are mainly used for continuous process control, where complex open or closed loop control tasks can be easily mapped into CFCs.

S7-PLCSIM: A simulator for S7-300, S7-400 or WinAC systems that allows testing of an S7 automation project in a virtual environment.

OB, FC, FB, DB blocks

In STEP 7, the program can be structured into blocks whose execution can be controlled.

- OB: organization blocks: for program management. In STEP 7, OB blocks are launched by the PLC, with certain OB blocks being launched by certain events. For example, when the PLC starts (for most Simatic S7 systems), OB100 is automatically run, if it exists, then OB1 is cyclically run (after OB1 execution is completed, this block is launched again). When an OB block is launched by the PLC, detailed information about the event that led to the execution of the OB block is transferred to the OB block interface, information that can be used in the user program.

- FC: Functions: contain user program sequences structured according to functional or process requirements, generally sequences for frequently used functions. Each function returns a single parameter (but as an extension of the IEC standard it is possible for a function to return several parameters). All output parameters of the block must be processed directly after the FC block is called.

- FB: Function Blocks: contain user program sequences structured according to functional or process requirements. FB blocks can be called with different input data for each call (so-called instance). This data, as well as internal variables (for storing intermediate values) and the block outputs, are saved in a data block (DB) allocated when the FB block is called and managed automatically by the system. This DB block, also called instance DB, should be unique for each FB block call and can be generated automatically when the program is compiled. The data in the instance DB blocks can be accessed at any time from the user program.

- DB: data blocks. They do not contain code and can be considered an extension of the working memory (PLC working memory area, denoted M in STEP 7). They can be global/generic data blocks (Shared DB), instance DB blocks pre-assigned to a certain FB block type (Instance DB), or predefined blocks according to a UDT template (DB of type...). Both elementary data types (BOOL, INTEGER, REAL, etc.) and complex data types (ARRAY, STRUCT, etc.) can be assigned to the data blocks.

- SFC: System Functions: are functions integrated into the CPU operating system, e.g. block transfer functions, time reading, etc.

- SFB: System Function Blocks: are function blocks integrated into the CPU operating system, e.g. SEND, RECEIVE, etc. Their variables are saved in data blocks, similar to FB function blocks.

- SDB: system data blocks. These are data blocks for the CPU operating system that contain system settings, e.g. module parameters, etc.

STEP 7 versions (excerpt):

STEP 7 integrated in TIA Portal

(starting with v10)

In April 2009, Siemens initiated a generational change in the Simatic S7 controllers by launching, first, the S7-1200 controller family. For their programming, a new version of the programming software was also released, initially called STEP7 Basic V10.5. Later, with the launch of version 11, the new software version was integrated into a complex development environment called TIA Portal (Totally Integrated Automation Portal), which includes, in addition to STEP 7, the WinCC packages (for programming operator panels), StartDrive (for parameterizing variable speed drives) as well as optional modules, depending on the version.

In the versions integrated in the TIA Portal, STEP 7 offers various options for configuring and debugging PLCs:

Hardware Editor: For configuring the automation system and parameterizing the modules that are settable.

Symbol Editor: For defining the global tags used, the symbolic names, data types and comments for them.

S7-PLCSIM: A simulator of Simatic S7 systems that allows testing an automation project in a virtual environment.

Program editor: For editing user programs using one of the standardized PLC programming languages (according to EN 61131-3):

- LAD (LADder logic, called KOP = Kontaktplan in German or LD according to IEC 61131-3). It is a graphical language according to DIN 19239 in which the user program is represented similar to an electrical diagram (American format - ladder diagram).

- FBD (Function Block Diagram, FBS – Funktionsbausteinsprache in German or FDB according to IEC 61131-3; similar to the CSF language from STEP 5). It is a graphical language according to DIN 40700 in which the user program is represented similar to an electronic diagram with logic gates.

Under TIA Portal (especially for S7 1200 and S7 1500 PLCs) the LAD and FDB languages offer a complete set of instructions and the program is transferred to the PLC directly in the language it was written in. Program blocks can be converted from LAD to FDB or vice versa but can no longer be converted directly into other languages (in STEP 7 versions v1.x to v5.x for S7 300 and S7 400 the program was interpreted in STL and LAD and FBD were program display modes).

- SCL (Structured Control Language, ST according to IEC 61131-3). It is a high-level language, based on the PASCAL language, which allows the use of complex language structures such as REPEAT-UNTIL, WHILE-DO, IF-THEN-ELSE, CASE, etc.

- Graph (Sequential Function Chart, SFC according to IEC 61131-3). A graphical programming language, which allows the implementation of sequential control structures, based on the concept of binary Petri nets. An S7-Graph program consists of a number of steps, each step having associated PLC program actions / equations, and a number of transitions that allow the transition from a certain step to another when certain conditions are met.

- STL (STatement List, called AWL = Anweisungliste in German or IL = Instruction List according to IEC 61131-3). It is a low level language, according to DIN 19239, similar to assembly language, with an extensive set of instructions that offers great flexibility in writing and optimizing the program. Control of program execution is achieved using Jump, BE instructions and function calls. Under TIA Portal, the STL language was implemented especially to allow the migration of projects developed in older versions (STEP 7 v5.x for example).

- CFC (Continuous Function Chart, Siemens specific, not IEC 61131-3 standard). A graphical editor used to create the entire PLC program structure from ready-to-program library blocks. In the editor, these blocks are selected in graphs, parameterized and interconnected. CFCs are mainly used for continuous process control, where complex open- or closed-loop control tasks can be easily mapped into CFC.

- CEM (Cause Effect Matrix) is a graphical programming language in which cause-effect relationships are directly defined. The program is defined in the form of a matrix in which various process events, called causes, trigger certain reactions, called effects.

TIA Portal History (excerpt):

Remove ads

References

External links

Wikiwand - on

Seamless Wikipedia browsing. On steroids.

Remove ads